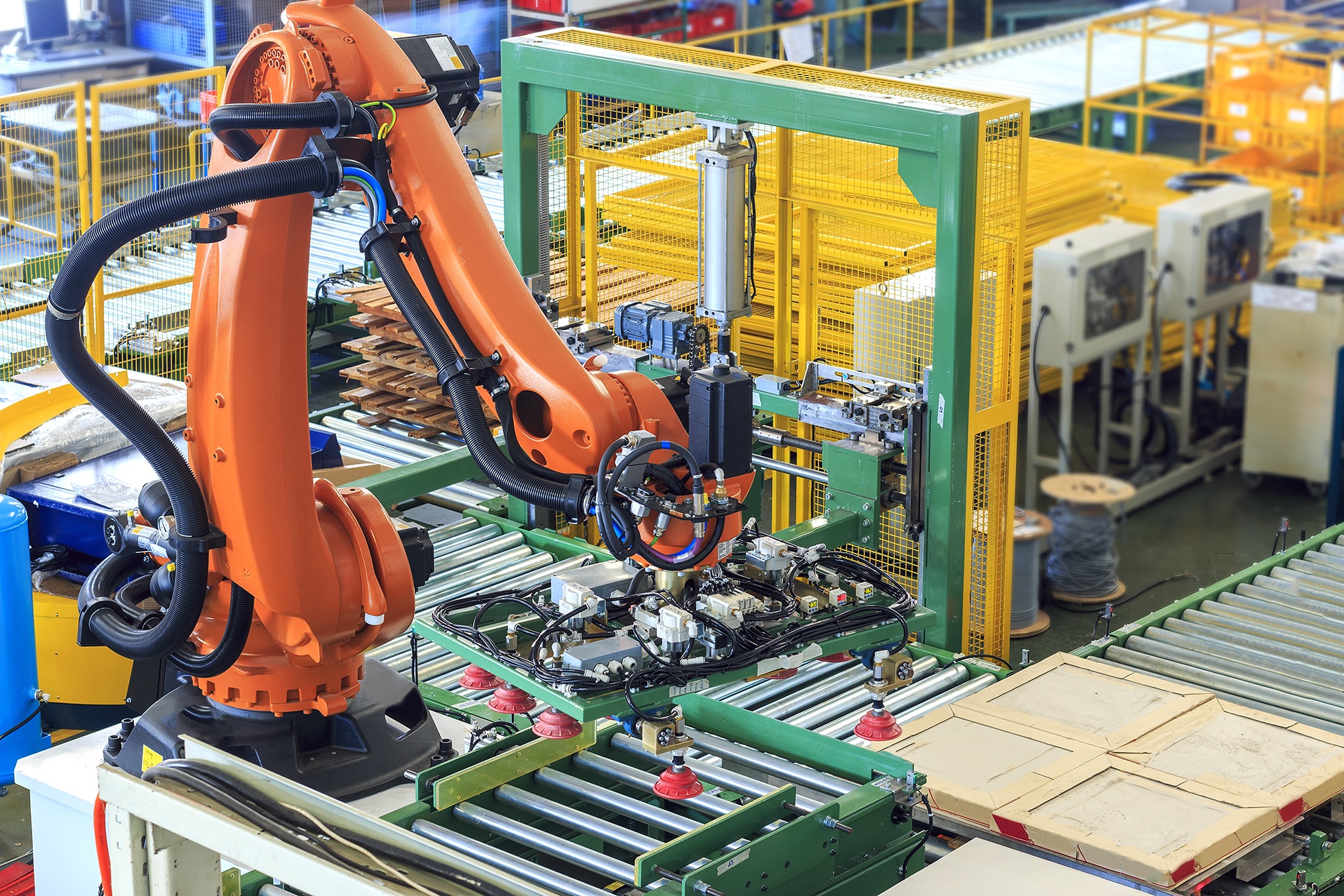

Over the past decade, our experienced team has been designing bespoke floor conveyor systems and routinely achieving every one of these results.

From in-floor conveyors to mezzanine conveyors, we have the ideal solution for your needs. To kickstart your journey, simply get in touch, and our specialists will be happy to share their expert, impartial advice.

If you’d like to see our recent conveyor-related projects and updates, follow us on LinkedIn.